Technology Development

Tobacco Elemental Technology / Device Elemental Technology

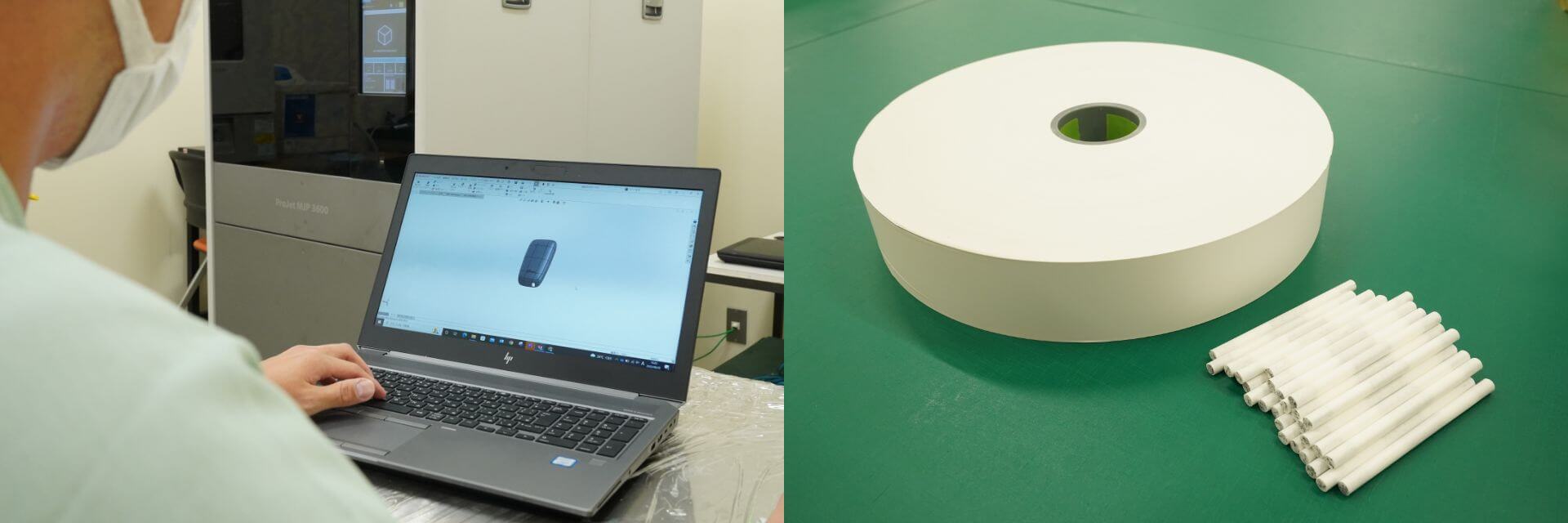

Creating never-before-seen technology and finishing it for practical application

Tobacco products are made by combining many different materials.

Technology Development is positioned between Science Research and Product Development. It has the function of creating new element technologies related to materials that constitute tobacco products as well as their manufacturing processes by acquiring hints and ideas from knowledge gained through Science Research, together with various forms of information such as academic papers and preceding cases.

Its role does not end with the creation of element technologies, but also includes application to production technology and investigations on introduction, with the goal of practical implementation.

Five key technologies required for creating tobacco products

The JT R&D Group works on the development of technologies required for tobacco products, classifying them into five categories. Four of these technologies—leaf blending, flavor, materials, and processing technology—are used to produce the tastes and flavors of tobacco products such as cigarettes as well as sticks and refills for Heated Tobacco Products and e-cigarettes. The fifth is device-related technology for heating sticks and refills. Since the raw materials and components handled by each elemental technology are different, development is generally carried out in parallel. But new raw materials may be developed by combining multiple elemental technologies, and demonstration experiments may be conducted by assembling elemental technologies.

Flavor Micro Chips

The JT R&D Group has flavorists that combine several flavors in their flavor mixing work. Flavors contain highly volatile compounds, meaning it is not easy to deliver the flavors created by flavorists to consumers as is. We have therefore developed a special substrate that can encapsulate flavors, and have succeeded in reducing the volatility of flavors and delivering ever-richer flavors. This substrate is called a Flavor Micro Chip and is included in some RRP*.

Tobacco granule for Ploom Tech

Tobacco granules made by processing tobacco leaves into granular form are encapsulated in heated tobacco for the JT Group’s Ploom TECH products, as flavor and taste sources, and these are not in cigarettes. Since these products use a low-temperature heating method, one of their weak points was a difficulty in bringing out their taste and flavor components and tobacco leaves couldn’t be used as a flavor source. This prompted the development of tobacco granules made by reshaping crushed tobacco leaves into granular form. These granules are highly efficient at releasing taste and flavor components, and their use has made it possible to successfully achieve tastes that are full and robust.

*Reduced-Risk Products: Products with the potential to reduce the health risks associated with smoking

Protecting intellectual property rights and contributing to the JT Group's assets

Much of the technical knowledge acquired through technological developments as well as the technologies developed are new to the world. Therefore, we not only incorporate them into our products but also actively protect them as intellectual property rights. From the early stages of development, the R&D personnel collaborate with intellectual property officers to share ideas and file patent applications at the optimal timing. Protecting intellectual property rights protects the uniqueness and reliability of the JT Group. It also plays an important role in ensuring a healthy market and safeguarding consumers by eliminating counterfeits and imitation products.

A sense of accomplishment achieved after refusing to give up and continuing to take on challenges

For R&D personnel engaged in the development of technology, creating something new is a process of trial and error until we succeed. Research and development does not always work out as planned. But we change the conditions over and over again, build a number of prototypes, and study them patiently. Because a certain technology has been completed by clearing a series of challenges, our personnel feel an indescribable sense of accomplishment when we succeed in development or when we see consumers holding a product we have been involved in.