Development of assessment method for indoor air quality

To achieve measurement of trace constituents at low concentrations

- Key Word

- #Indoor air quality

- #Assessment method

- #Measurement of trace constituents

Development of assessment method for indoor air quality

The JT R&D Group is conducting research of RRP* such as Heated Tobacco Products (hereafter HTP) using various approaches on reducing the on reducing the disturbances caused to surrounding people , and is announcing the content of its research through such as JT Science. This project was launched to carry out studies on indoor drifting smoke and vapors, such as those present in smoking rooms, and to analyze the extent to which constituents derived from tobacco products are generated by RRP* in indoor air environments.

How can constituents in extremely low concentrations be collected and quantified? They came together as a team to address this difficult issue.

*Reduced-Risk Products: Products with the potential to reduce the health risks associated with smoking

PROJECT MEMBER

-

Scientific Product Assessment

Yuichi Fukai

Responsible for developing methods to analyze trace constituents contained in tobacco smoke and vapor. Responsible for proposing assessment systems in response to consultation and requests related to chemical assessment of development items and products from various related departments, and operations to advance the development of analytical methods required for those assessments.

-

Scientific Product Assessment

Yoshihiro Enomoto

Conducted project leading work for indoor air quality assessments. Responsible for development of analytical methods necessary for assessment, management of requested tests, and also work to update laboratory equipment and submit papers on acquired data.

-

Scientific Product Assessment

Ryosuke Imai

Primarily responsible for procedures to collect and analyze heavy metals in the development of trace constituent analysis methods for indoor air quality assessments. Duties also included a position as member of a promotion committee for the maintenance of laboratory accreditation related to the analysis of tobacco products.

PROJECT STORY

01.Background

To measure small quantities of constituents generated by RRP*

The JT R&D Group has been active in releasing the results of its research on tobacco products to the public, so there has been a growing movement within the JT Group to conduct similar types of analysis on RRP*. However, some of the constituents generated by RRP* which were to be studied had concentrations considerably lower than cigarettes. Low concentrations not only make qualification and quantification difficult, but raise the difficulty of sample collection as well. This project was started by gathering together professionals in the field of chemical analysis, to carry out measurement of trace constituents in low concentrations. Stable quantification of trace constituents is not possible simply by reapplying existing analytical methods. Therefore, the project team members made the decision to establish a new assessment method by creating a measurement method from the very beginning. They thought deeply about making attempts that utilized currently-existing analytical equipment, and proceeded with both concern and anticipation for their work.

*Reduced-Risk Products: Products with the potential to reduce the health risks associated with smoking

02.Approach

Development of assessment methods by utilizing the specialized expertise of diverse members

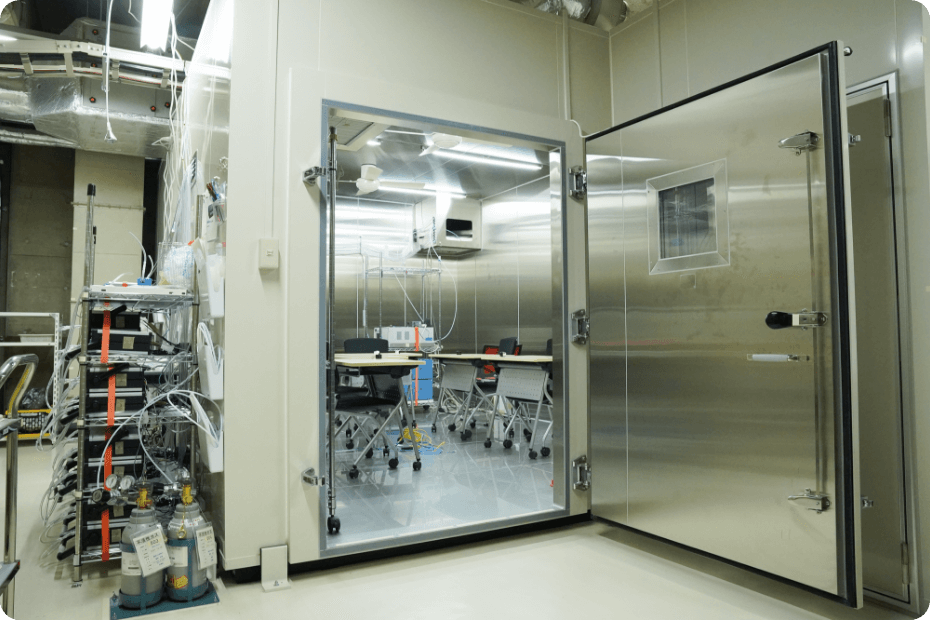

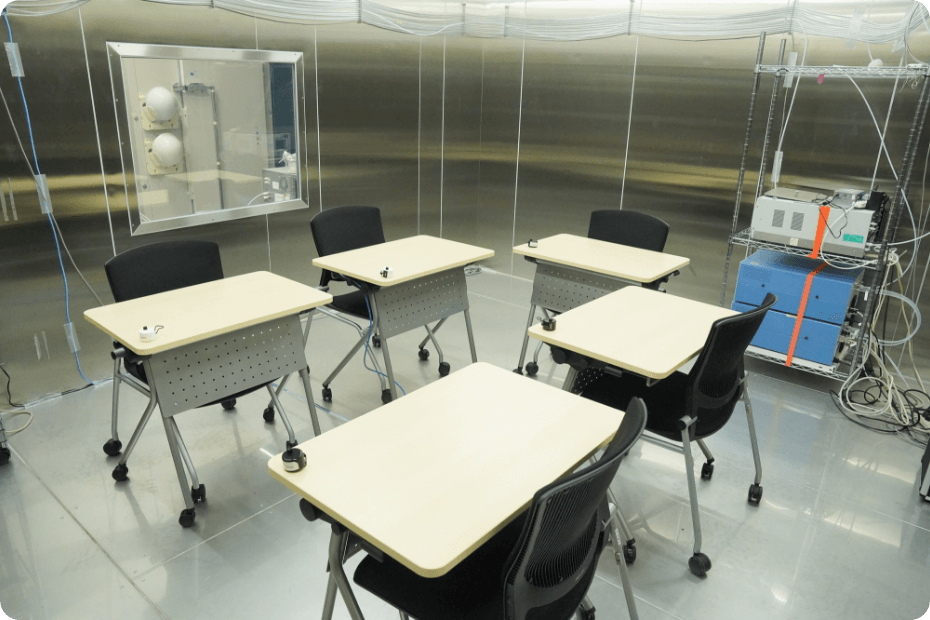

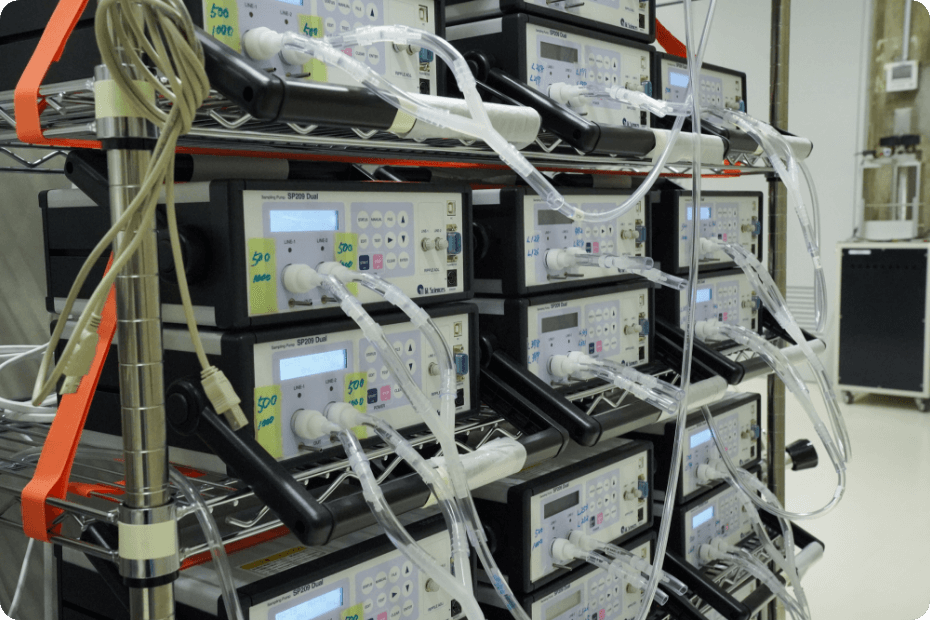

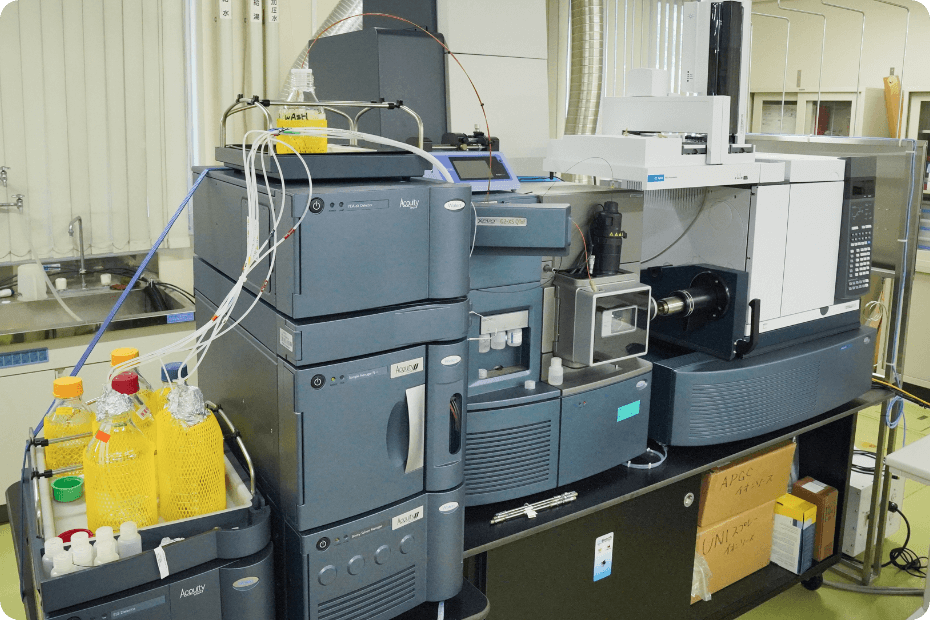

The constituents released into the air during the use of RRP* were quantified through three processes: collection, extraction, and analysis. The first process was collection. RRP* was used in a testing room designed with reference to the standards used for air quality measurement, and the constituents drifting through the air were made to adhere to a collector installed in the room. The next steps were extraction and analysis. There were some constituents that could be analyzed according to existing international standards, but for constituents whose analysis methods had not yet been established or for which high-sensitivity measurement was required, a new high-sensitivity analysis method developed by the team was used. Since there were several dozen types of constituents to be analyzed, it was impossible to analyze all of them under the same conditions. They were therefore classified according to their chemical properties, and the project members divided up the work for examining each analysis condition among themselves.

In addition to chemical analysis professionals, members with diverse backgrounds gathered together to demonstrate their own individual specialties and steadily proceeded in carrying out their designated tasks. By assembling the knowledge and efforts of each member in the form of a team, it was possible for a high-quality assessment method to be developed.

For example, one process in the method involved using a filter to collect a certain constituent from the air, and that collection method was proposed by a member who was in the first year with the company at that time. Commercially available filters contain small quantities of the target constituent, so if analysis was carried out without any prior processing, there was an issue of difficulty in determining whether the measured constituent was derived from the filter or the collected air. The new employee member of the team developed a method of effectively eliminating the quantity of the constituent which was originally contained in filters, making it possible to measure only the quantity of the constituent derived from tobacco products. This collection method is still used as a measurement standard within the JT Group.

Incidentally, the new employee member apparently devised this collection method as a personal challenge during new employee training, and said, “I really felt that it was a workplace with a culture of taking in the ideas of even new employees.”

*Reduced-Risk Products: Products with the potential to reduce the health risks associated with smoking

03.Results

Creating analytical methods with a strong sense of responsibility is truly a part of product development

In addition to the cooperation of members with strong information gathering skills and high technological capabilities, they received cooperation from the in-house laboratory which has extensive capabilities for analytical processing. This allowed them to move forward with the development of analytical methods for many types of measurement items without delay. They proceeded with the project by paying strict attention to the development of technology to measure the amounts of ultra-trace constituents, without having to set limits on the levels that could be reached from a technological standpoint. Together with establishing an assessment and testing system for constituents derived from new tobacco products, they were able to obtain evidence proving that the impacts of the JT Group’s HTP on indoor air quality are lower than those of cigarettes, and could acquire important data to announce and communicate the characteristics of HTP to the public.

As a part of efforts to publicize the project, the project members also released papers and presented them at academic conferences in Japan and overseas, actively communicating the project results to external sources. We believe that by allowing the world to gain an understanding of one part of the JT R&D Group's capabilities for analysis and assessment, it can contribute to creating a future in which our products themselves will be trusted.

The development of assessment methods carried out in this project is not work that ends just with the creation of a proper analytical method. It is precisely because this assessment method exists that we can be even more confident and deliver high-quality tobacco products to consumers. That is why they were able to lead the project to success while experiencing feelings of great motivation and pride.

*Reduced-Risk Products: Products with the potential to reduce the health risks associated with smoking